GEOTEXTILES| Precast Concrete Sales Company

TerraTex Barrier Fencing

Fabric Rolls

- 48″ x 300′

- 48″ x 100′

Preassembled Fences

- 48″ x 100′

- 48″ x 50′

Special lengths available upon request

Please refer to the filter fabrics section in our catalog link.

Mutual Industries

Mutual Industries manufactures a broad line of Econofence® preassembled silt fences designed to meet the various state highway, environmental and private specifications. Listed below are commonly produced fences. All are 100 feet long, utilizing wooden posts and sedimentation control fabric.

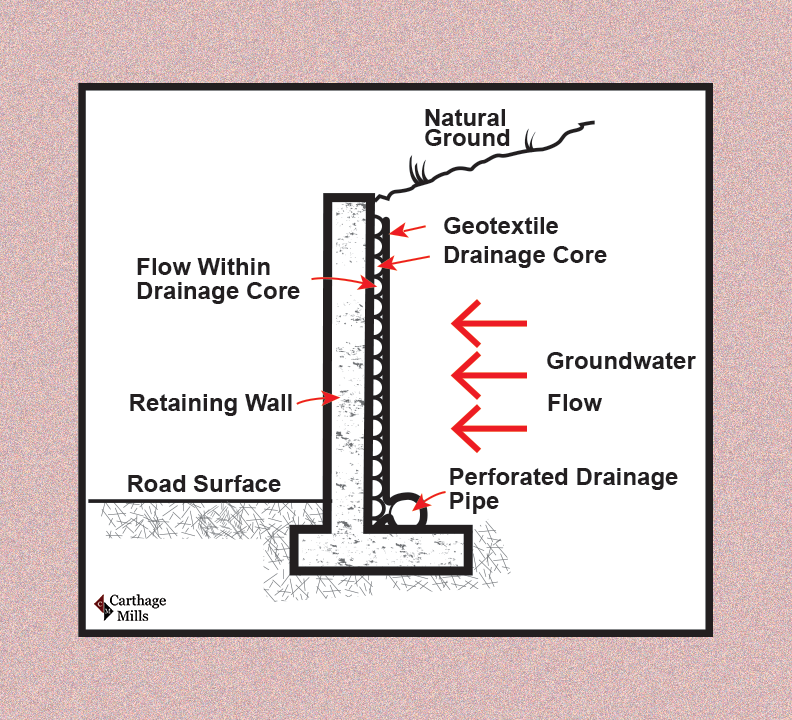

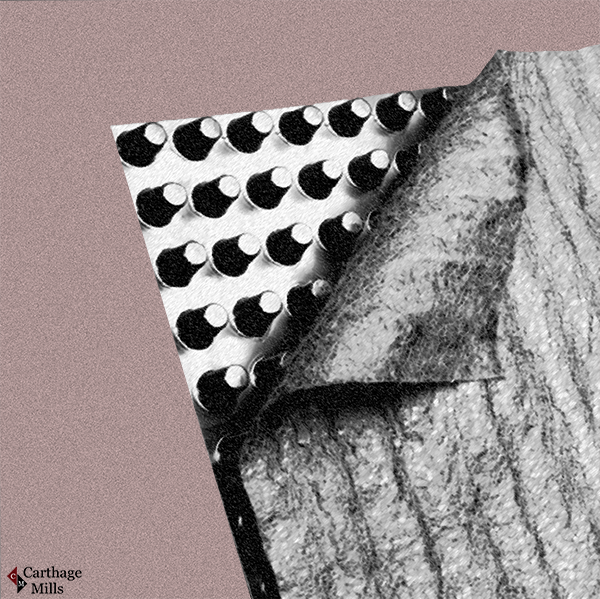

Conventional aggregate drainage systems are costly and difficult to install.

DX-400B/4 Sheet Drains offer a modern, cost-effective drainage alternative. They replace aggregate backfill in many drainage applications. DX-400B/4 reduces hydrostatic pressure and conveys ground water away from structure. Protection board systems can often be enhanced or replaced by DX-400B/4 Drainboard.

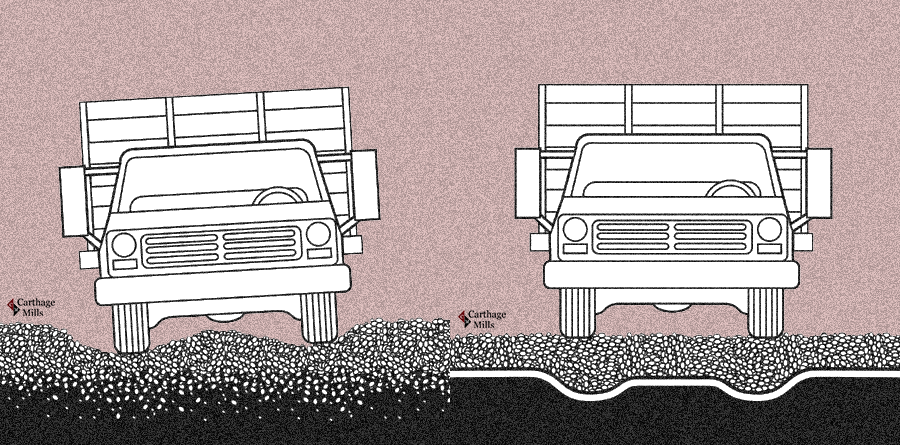

SEPARATION

Intermixing of Subgrade & Aggregate

Traffic loads (or compaction during construction) typically cause a mixing of the high cost aggregate and subgrade. This intermixing can occur in both paved and unpaved structures. As the subgrade pumps into the aggregate, the supportive strength of the aggregate is lost and rutting or pavement cracking can result (LEFT image). FX-55 with its high puncture resistance, acts as a barrier to prevent this wasteful mixing.

REINFORCEMENT

Intermixing of Subgrade & Aggregate

FX-55 is put into tension as traffic loads are applied. The extremely high modulus (resistance to stretching) of FX-55 causes it to absorb those loadings and distribute them over a large area. The resulting decrease in pressure on the subgrade can result in a significant reduction in required aggregate depth (RIGHT image).

CARTHAGE MILLS FX-66

Carthage Mills FX-66 goes a step beyond most fabrics by offering the engineer and contractor:

- Greater strength to stabilize very poor soils or to withstand extremely demanding installation conditions (i.e., placement of armor stone or railbed rehabilitation).

- A greater degree of safety in design for marginal soil conditions

- Economical pricing in comparison to other high strength construction fabrics.

- Light roll weight for ease of handling in the field.

- Prolonged resistance to ultraviolet degradation.

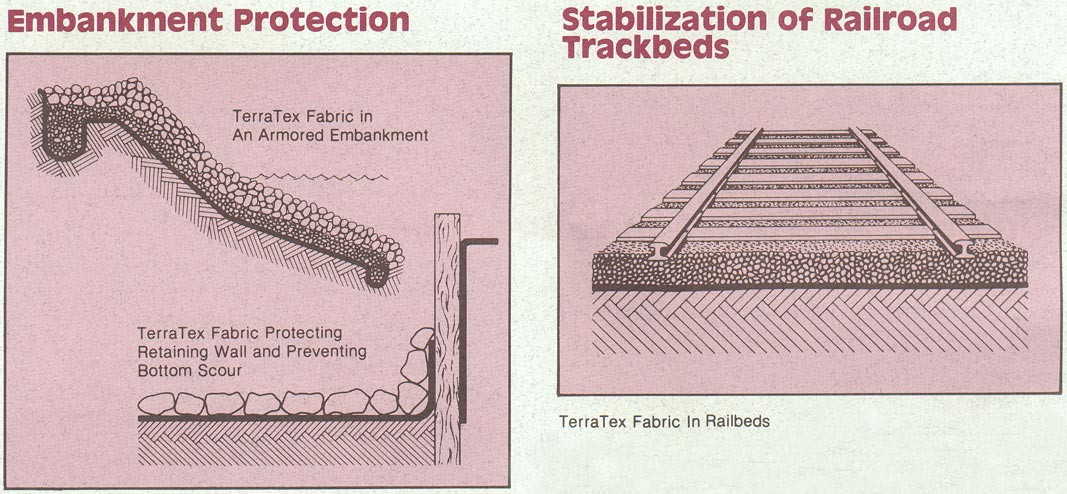

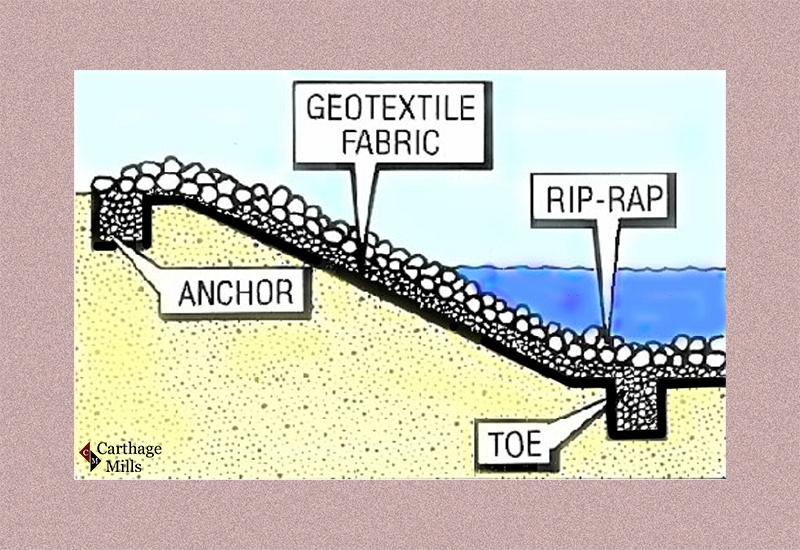

Protection of embankment and slopes against erosion has long been a structural and environmental problem. Re- taining walls and various types of armor stone have proven to be a partial solution as they absorb the major forces exerted by water movement. Unfortunately, such methods are often threatened because the native soil may be scoured from be- hind structures by the more subtle water movements.

In the 1960’s the Corps of Engineers experimented with and determined that geotextiles can be effective in controlling this scouring out of native soils from behind embankments and slope protection structures. Carthage 6% has been manufactured to exceed or meet the fabric specifications of the Corps of Engineers for such applications.

Carthage 6% is recommended for embankment protection where specifications call for or conditions merit a very robust fabric. It may also be used for subsurface drainage protection and siltation control.

CATALOG DOWNLOAD| Precast Concrete Sales Company

Tap the orange button below to download your

Precast Concrete Sales Company CATALOG

Hours•Phone•Email

MONDAY: 7:00 - 5:00

TUESDAY: 7:00 - 5:00

WEDNESDAY: 7:00 - 5:00

THURSDAY: 7:00 - 5:00

FRIDAY: 7:00 - 5:00

SATURDAY: 7:30 - 11:30

SUNDAY: CLOSED

pcsinfo@precastconcretesales.com

WE DO NOT DELIVER OUT OF

THE TRI-STATE AREA